The Start of a Million Decisions

Stalker mode: Activated!

Before we even reached out to Schionning designs, we tracked down the owners of other Aussies who had built/ were building an Arrow series yacht. Thanks to Facebook and Marine Traffic, we were able to talk to several people and picked up some valuable bits of information. We also picked the brains of some very knowledgeable friends and work mates that had a lot of sailing experience - I’m sure they are almost sick of us asking questions by now!

Some of our initial considerations were;

Vessel size - the Arrow range comes in a 12m, 12.8m, 13.6m and 15m versions

Hull material: the kits are available in foam or balsa cores

Engine configuration - sail drive, shaft drive or outboard

Where we were actually going to build this thing!

After much deliberation, we decided on the 13.6m option - everyone we talked to agreed that we should be building the longest vessel possible if we wanted to take this thing blue water sailing (we have BIG adventures planned for our yacht!). So why not the 15m version, you ask? Well. It just wouldn’t fit in our shed! We do have room to build a dome - type ‘shed’ on our property, but considering the strength of the winds we get here in Dongara over summer, I don’t think it’d be long before it got ripped, and the sand and dust flying around an area we are trying to glass in isn’t ideal. Another option was to try rent one of the sheds out in the industrial area, but that’s a lot of extra money when we could build in our backyard. So the 1360 will be born in our existing shed, which is just big enough. We will have to pull the end off the shed when launch day comes, but it will be so much more convenient having it only a minutes walk away, in a secure and watertight location.

One of the aspects of the Schionning design we loved was the construction method. Our vessel will be delivered very much similar to that of an aluminium kit boat - flat packed, with CNC cut pieces into multiple sheets that will be 2400mm x 1200mm. These sheets will be pre- laminated, so the majority of fibreglassing we will be doing is ‘taping’ - which is joining the pieces together to form frames/stringers/bulkheads etc, and then taping together to form our hull. For the less boat orientated, think of it like the ultimate 3D jigsaw!

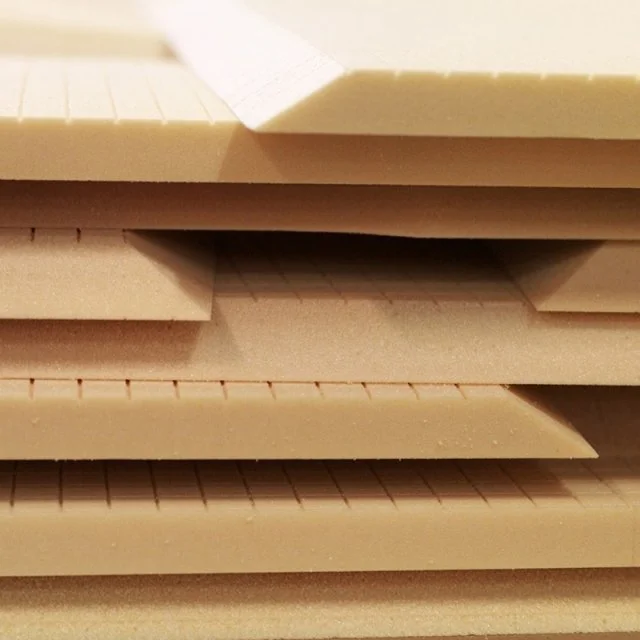

Stack of DuFlex panels, CNC cut

Which leads us onto the next major decision, the hull material. When talking to the other Arrow builders in Australia, the majority of them had constructed with end grain balsa cores. Our preference had always been a foam cored vessel, because we have already spent a large chunk of our time rebuilding boats with rotted wooden stringers and transoms, and did not want to have the possibility of wood rot in the future. We did get a bit concerned when we found that so many other owners had opted for the balsa core option… but most of these builders were either nearing the end of a 5 year project, or had completed their vessels, and at the time of purchasing their kits the balsa core was significantly cheaper. Balsa also has a higher compression strength and greater stiffness compared to the foam, and has been used in vessel construction for a very long time. Whilst foam (as a core alone) is lighter, it needs to have a bit more glass around it to achieve the same strength, so in the end the two vessels weight work out similar. The major disadvantage of balsa is that it will absorb water if the core is exposed, slowly soaking through the balsa until cut out. Theoretically, if you do a good job of the glassing, it shouldn’t be a problem - but remember that every screw you put into the deck has to be properly prepared and sealed, or it will rot with water ingress. Now think of how many fixtures go into a boat - the potential for the rot to occur at some stage of the vessels life is pretty high.

The foam panels we will be supplied are called DuFlex. The foam is Divinycell H, and will be laminated over with 600gm biaxial e- glass and epoxy resin, and finished off with a layer of peel ply for a smooth finish. Put simply - it’ll be structural foam covered in fibreglass each side. The foam does not absorb water, and with the way the foam cells are constructed, if we get water intrusion it will not spread like the balsa. Yes, it will have to be properly dried out and fixed before re glassing, but we shouldn’t be cutting out huge amounts (touch wood - or foam). Other benefits include excellent adhesion/ peel strength, excellent chemical resistance and good thermal and acoustic insulation. While all this talk of materials might sound a bit mundane, I found it really interesting to see the weight, deflection and pressure to failure comparisons between a DuFlex panel, aluminium sheet and steel sheet - have a google if you’re interested.

Divinycell H foam

Probably one of the easier decisions was that we were not going to install outboards as our propulsion. There is so little places on the WA coast where you can get unleaded on the wharf, and carting fuel cans around will take up a lot of space and be a bit of a logistical headache if we don’t have a car when we need to refuel. We’ve committed to putting sail drives in over a shaft drive set up, mostly because it’s more compact and allows the layout we wanted - if we went shaft drive, the engine would have to be much further forward, and ruins our layout plan (which you’ll see shortly!). We are thinking that a saildrive will be easier to install, but I’ve never done one before, so I could be completely wrong on this - as they say, that’s a problem for 'Ron!

Next up - the actual design process with Schionning!